Corporate Workwear Supplier in Enterprise Uniform Management

In corporate environments, workwear is rarely limited to protection or durability alone. Uniforms also carry brand identity, role differentiation, and organizational discipline. As companies scale across locations and departments, the complexity of managing workwear increases rapidly. In this context, a corporate workwear supplier is evaluated not only on product quality, but on its ability to support consistency, coordination, and long-term supply control.

These challenges often emerge after the initial rollout, not during the first delivery.

Why Corporate Workwear Requires a Different Supply Model

Uniform Programs as Ongoing Systems

Corporate workwear programs are continuous by nature. New employees join, departments expand, and garments are reordered over time. Without a structured supply model, variation gradually appears in color tone, fit, and construction details.

A corporate workwear supplier addresses this by treating uniforms as part of an ongoing system rather than a one-time order.

The Cost of Inconsistency

Small inconsistencies—such as logo placement shifts or fabric changes—may seem minor, but they undermine professional appearance and complicate internal management. Over time, they increase replacement cost and reduce employee acceptance.

Product-Level Requirements in Corporate Workwear

Balancing Professional Appearance and Daily Wear

Corporate workwear must maintain a clean, professional look while withstanding frequent use. Unlike heavy industrial garments, excessive stiffness or bulk can reduce comfort and visual consistency.

Key product characteristics include:

-

Stable fabric structure that resists deformation

-

Controlled reinforcement that preserves appearance

-

Color consistency across repeated production runs

A corporate workwear supplier designs garments with both appearance and wear cycle in mind.

Fit Consistency Across Roles and Locations

Corporate programs often span offices, logistics teams, and field staff. Size grading accuracy becomes critical when garments are issued across different sites.

Manufacturers supporting corporate programs validate grading templates early to ensure consistent fit throughout the organization.

Scenario-Based Advantages in Corporate Workwear Supply

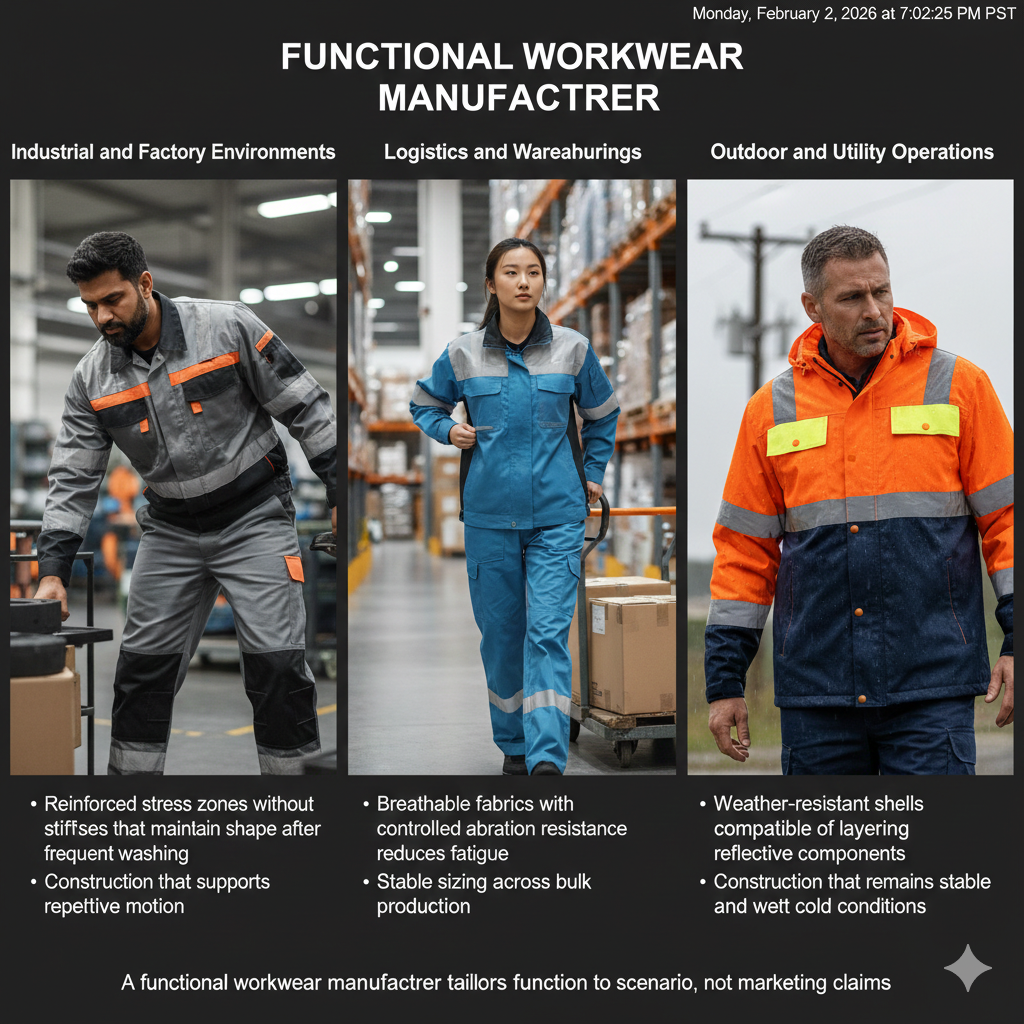

Office and Client-Facing Roles

For front-facing roles, workwear emphasizes clean lines, comfort, and brand alignment. Fabrics are selected for shape retention and easy maintenance rather than heavy abrasion resistance.

Logistics and Operations Teams

Operational staff require greater durability while still maintaining a consistent corporate image. Garments must handle movement and washing without deviating from brand standards.

Field and Outdoor Staff

Corporate field teams often combine visibility, weather resistance, and branding. Workwear design integrates reflective elements and layered construction without compromising identity consistency.

A corporate workwear supplier aligns these different needs under one coordinated supply framework.

Manufacturing and Supply Discipline Behind Corporate Programs

Repeatability Over One-Off Quality

Corporate programs depend on repeatability. Materials, trims, and construction details are documented to ensure future orders match earlier deliveries, even when placed months apart.

Coordinated Manufacturing Services

Integrated manufacturing services—covering material continuity, construction standards, and process control—reduce disruption when programs expand or change internally.

This service-oriented approach differentiates professional suppliers from transactional vendors.

Supply Model Comparison: Generic Uniform Vendor vs. AOKENEW

| Evaluation Aspect | Generic Uniform Vendor | AOKENEW Corporate Supply Model |

|---|---|---|

| Program perspective | Order-based | System-based |

| Brand consistency control | Limited | Documented and repeatable |

| Multi-role coordination | Fragmented | Integrated |

| Reorder stability | Variable | Controlled |

| Scalability | Reactive | Planned |

| Long-term cost control | Unpredictable | More stable |

This distinction explains why enterprises increasingly view workwear supply as a management function rather than a procurement task.

MOQ, Lead Time, and Customization in Corporate Programs

MOQ Planning for Enterprise Rollouts

MOQ is structured to support both initial deployment and future onboarding needs. Flexible planning helps prevent fragmentation across departments.

Lead Time Predictability

Lead time is managed through defined stages—sampling, material allocation, and production—ensuring reliable delivery across different business units.

Customization With Brand Control

Logos, trims, and color standards are locked early to maintain brand integrity across all garments and reorders. A corporate workwear supplier integrates customization into a controlled system rather than handling it case by case.

Frequently Asked Questions

How does a corporate supplier differ from an industrial workwear supplier?

Corporate suppliers balance appearance, branding, and comfort alongside durability, while industrial suppliers focus primarily on protection.

Can corporate workwear programs scale over time?

Yes. When materials and specifications are documented, programs can expand without losing consistency.

What should enterprises confirm before mass rollout?

Brand standards, size grading, material continuity, and reorder procedures should all be finalized during sampling.

Closing Perspective

Working with a corporate workwear supplier is about maintaining organizational consistency as companies grow and evolve. When product design, manufacturing processes, and supply coordination are aligned, corporate workwear becomes easier to manage and more reliable over time.

AOKENEW supports corporate workwear programs through structured manufacturing workflows, coordinated product systems, and disciplined supply management across woven workwear, jackets, vests, and functional apparel. An overview of our capabilities and product categories is available on our homepage: https://www.aokenew.com.

If you have related requirements or questions—such as aligning brand standards across departments, planning phased rollouts, or managing reorders efficiently—you are welcome to contact our team directly via Contact Us: https://www.aokenew.com/contact-us.