Industrial apparel is not defined by style or seasonality. It is defined by exposure—to abrasion, repeated motion, weather variation, and industrial laundering. For this reason, an industrial apparel manufacturer is evaluated by how effectively it converts environmental stress into controlled design and manufacturing decisions.

The real test begins after garments leave the warehouse and enter daily use.

Why Industrial Apparel Requires Specialized Manufacturing

Industrial Conditions Are Inherently Uneven

Unlike controlled workplaces, industrial environments apply stress unevenly. Knees, elbows, shoulders, and pocket areas experience concentrated wear, while other zones remain relatively unaffected. Apparel designed without this understanding often fails prematurely.

An industrial apparel manufacturer begins with mapping stress patterns rather than copying standard garment templates.

Durability Without Overbuilding

Overbuilt garments increase stiffness, heat retention, and cost. Underbuilt garments shorten service life. The challenge lies in reinforcing where necessary while preserving mobility and comfort.

This balance is achieved through engineering discipline, not visual inspection.

Material and Structural Engineering in Industrial Apparel

Fabric Selection Based on Exposure, Not Trend

Fabric choice in industrial apparel prioritizes abrasion resistance, dimensional stability, and wash durability. Woven structures are often selected for high-contact environments, while knit structures are reserved for lower-abrasion roles.

Material decisions are guided by:

-

Expected contact with tools and surfaces

-

Frequency and method of industrial laundering

-

Temperature and moisture exposure during use

An industrial apparel manufacturer selects fabrics for predictable behavior over time, not initial appearance.

Structural Reinforcement as a Load-Management Tool

Reinforcement in industrial apparel is applied selectively. Bartacks, double stitching, and layered panels are placed at stress concentrations rather than distributed uniformly.

This approach:

-

Extends garment lifespan

-

Maintains freedom of movement

-

Controls material and labor cost

Structure serves function, not decoration.

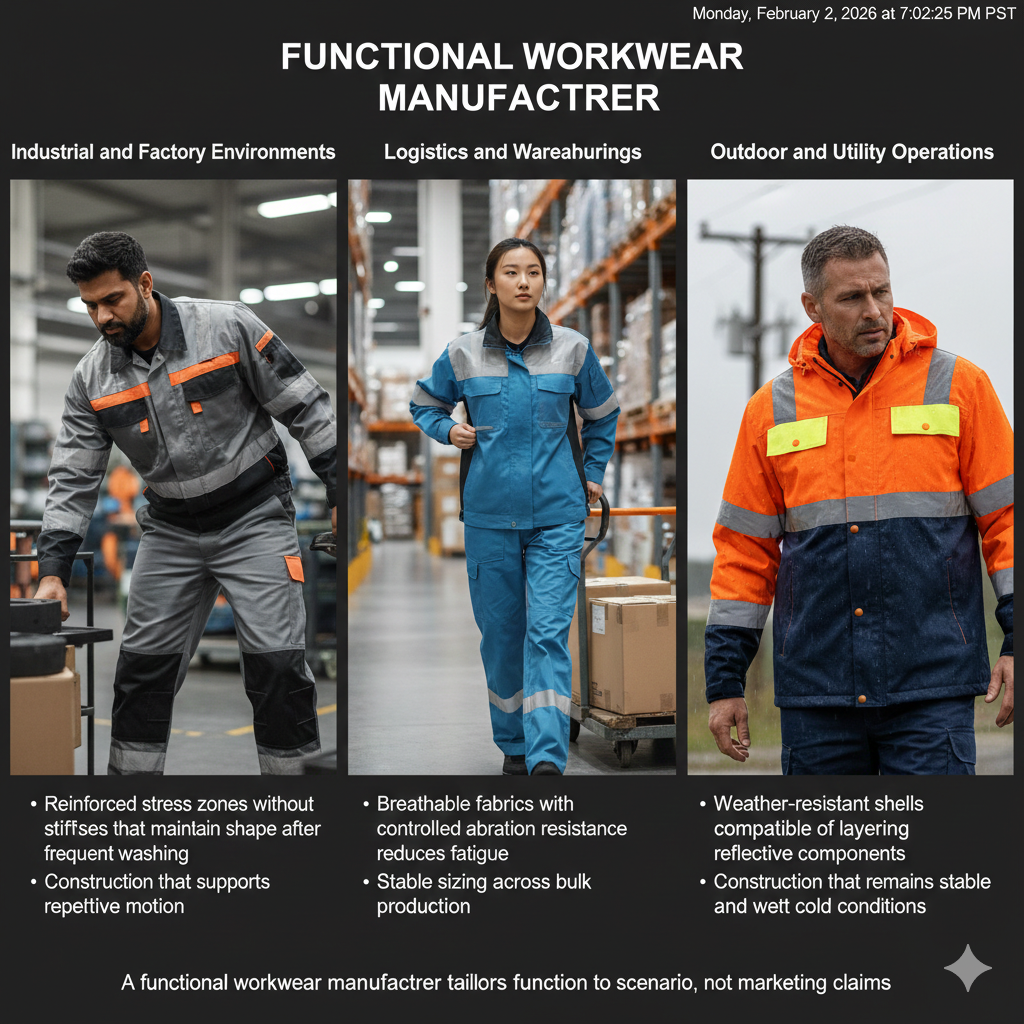

Scenario-Based Strengths Across Industrial Applications

Manufacturing and Factory Operations

Factory garments must tolerate repetitive motion and constant friction. Apparel in this scenario emphasizes abrasion resistance, stable sizing, and comfort during long shifts.

Logistics, Warehousing, and Distribution

In logistics environments, garments must remain lightweight while resisting surface wear. Frequent washing demands fabric stability and seam integrity at scale.

Outdoor and Infrastructure Work

Outdoor industrial roles combine weather exposure, visibility needs, and layered use. Apparel must integrate protective and functional elements without compromising durability or fit consistency.

An industrial apparel manufacturer differentiates products by scenario rather than offering one universal solution.

Manufacturing Discipline and Consistency Control

Process Control Over End-Stage Inspection

Consistency in industrial apparel comes from repeatable processes. Fabric allocation, cutting tolerances, and sewing sequences are standardized to minimize variation across large production runs.

Quality management systems such as ISO 9001 emphasize this process-based approach, particularly for products requiring stable output over time.

Reference: https://www.iso.org/iso-9001-quality-management.html

Size Grading and Workforce Fit

Accurate size grading is essential for workforce acceptance. Small deviations multiply across large teams, leading to discomfort, returns, and replacement costs. Professional manufacturers validate grading before bulk cutting begins.

Manufacturing Model Comparison: General Apparel vs. Industrial Apparel

| Evaluation Aspect | General Apparel Manufacturing | Industrial Apparel Manufacturing (AOKENEW) |

|---|---|---|

| Design logic | Style- or trend-driven | Exposure- and use-driven |

| Fabric selection | Appearance-focused | Durability- and stability-focused |

| Reinforcement strategy | Minimal or uniform | Stress-zone targeted |

| Scenario adaptation | Limited | Designed per environment |

| Batch consistency | Variable | Controlled |

| Long-term performance | Unpredictable | More reliable |

This contrast explains why industrial buyers prioritize lifecycle performance over initial unit pricing.

MOQ, Lead Time, and Customization in Industrial Apparel

MOQ Planning for Industrial Programs

MOQ is structured to align material sourcing efficiency with production flow. Orders below optimal thresholds often introduce substitutions that affect durability and consistency.

Lead Time Predictability

Lead time is managed through defined stages—sampling, material allocation, production, and final assembly. Structural changes after sampling remain a primary cause of delay.

Customization With Structural Integrity

Logos, trims, and functional details are integrated without compromising reinforcement zones or garment balance. An industrial apparel manufacturer treats customization as part of engineering, not surface decoration.

Frequently Asked Questions

How is industrial apparel different from standard workwear?

Industrial apparel is engineered specifically for high-stress environments and repeated use, rather than general workplace appearance.

Does higher durability always increase cost?

Not necessarily. Targeted reinforcement and material selection often reduce replacement frequency and total program cost.

What should buyers confirm before mass production?

Fabric behavior, reinforcement layout, size grading, and customization impact should all be finalized during sampling.

Closing Perspective

Working with an industrial apparel manufacturer is ultimately about controlling performance under demanding conditions. When environmental exposure, garment structure, and manufacturing discipline are aligned, industrial apparel programs become more predictable and easier to manage over time.

AOKENEW supports industrial apparel programs through disciplined manufacturing workflows, scenario-driven product engineering, and consistent production control across woven garments, jackets, vests, and functional apparel. An overview of our manufacturing capabilities and product categories is available on our homepage: https://www.aokenew.com.

If you have related requirements or questions—such as matching apparel to specific industrial environments, planning durable garments at scale, or aligning customization with repeat orders—you are welcome to contact our team directly via Contact Us: https://www.aokenew.com/contact-us.