Functional Workwear Manufacturer: Engineering Durability, Comfort, and Protection for Real Work Conditions

In industrial and commercial uniform programs, “function” is often misunderstood as a checklist of features—waterproof, breathable, reflective, insulated. In practice, these features interact, compete, and sometimes cancel each other out. A functional workwear manufacturer is therefore judged not by how many functions are claimed, but by how well those functions are engineered to work together under real conditions.

The difference becomes clear only after garments are worn, washed, and relied upon daily.

What Makes Functional Workwear Fundamentally Different

Function as a System, Not a Label

Functional workwear is designed around use behavior. Movement patterns, exposure time, environmental stress, and laundering frequency all influence which functions matter and how they should be prioritized.

Poorly engineered functional garments often fail because:

-

Breathability is sacrificed for waterproofing

-

Insulation restricts movement

-

Reflective elements degrade after washing

A functional workwear manufacturer manages these trade-offs intentionally rather than adding features independently.

Engineering Function Through Materials and Structure

Material Selection Based on Performance Interaction

Material choice in functional workwear is less about premium fibers and more about performance compatibility. Outer shells, linings, and reinforcements must work together without creating stiffness, overheating, or premature wear.

Professional manufacturers evaluate materials based on:

-

Moisture and heat transfer behavior

-

Abrasion resistance under movement

-

Stability after repeated industrial laundering

Function is engineered at the material interface, not at the surface.

Structural Design That Enables Function

Garment structure determines whether materials can perform as intended. Ventilation zones, articulated panels, and reinforcement placement all affect how functions are expressed during use.

Over-structuring reduces mobility. Under-structuring shortens lifespan. Balance is deliberate.

Scenario-Based Functional Advantages

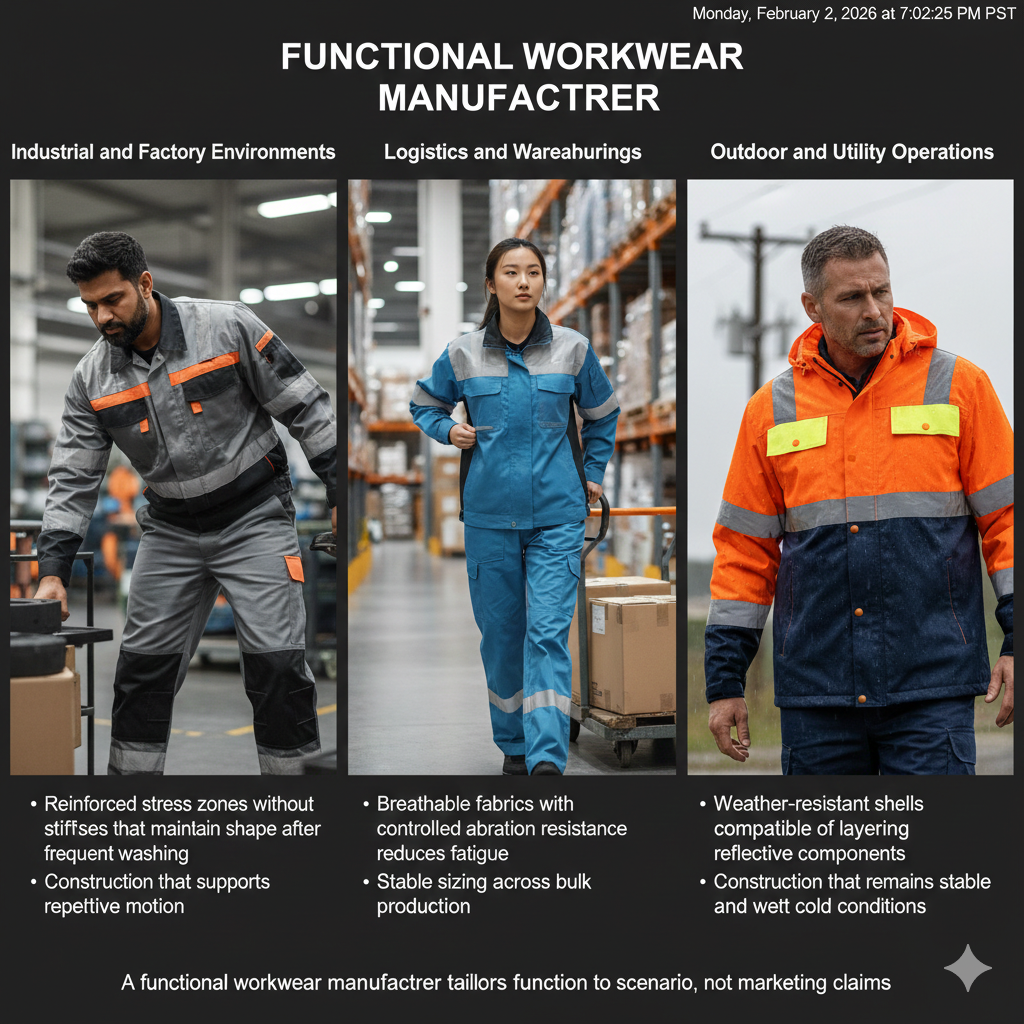

Industrial and Factory Environments

In factories, functional priorities center on durability, freedom of movement, and thermal balance. Garments must endure friction and repetitive motion without restricting the wearer.

Functional advantages here include:

-

Reinforced stress zones without full-body stiffness

-

Fabrics that maintain shape after frequent washing

-

Construction that supports repetitive motion

Logistics and Warehousing

Warehousing environments demand lightweight functionality. Workers alternate between motion and rest, often indoors, with frequent washing cycles.

Key functional characteristics include:

-

Breathable fabrics with controlled abrasion resistance

-

Flexible construction that reduces fatigue

-

Stable sizing across bulk production

Outdoor and Utility Operations

Outdoor roles combine weather exposure, visibility, and layering requirements. Functional workwear must adapt to changing conditions without constant garment changes.

Here, functional engineering focuses on:

-

Weather-resistant shells compatible with layering

-

Durable integration of reflective components

-

Construction that remains stable in wet and cold conditions

A functional workwear manufacturer tailors function to scenario, not marketing claims.

Manufacturing Discipline Behind Functional Performance

Process Control as a Functional Safeguard

Functional performance depends on repeatability. Variations in seam tension, fabric batch behavior, or reinforcement placement can undermine intended functions at scale.

Manufacturers following ISO 9001 quality management principles emphasize process documentation and control to ensure functional consistency across batches.

Reference: https://www.iso.org/iso-9001-quality-management.html

Size Grading and Functional Fit

Fit affects function. Poor grading restricts movement or compromises insulation and ventilation performance. Professional manufacturers validate grading before bulk production to protect functional intent.

Functional Manufacturing Models: Feature-Driven vs. AOKENEW

| Evaluation Aspect | Feature-Driven Manufacturing | AOKENEW Functional Model |

|---|---|---|

| Definition of function | Feature list | Use-condition driven |

| Material selection | Isolated performance | Performance interaction |

| Structural design | Standard templates | Scenario-specific |

| Manufacturing control | Reactive | Process-controlled |

| Functional consistency | Variable | Stable |

| Long-term performance | Unpredictable | More reliable |

This distinction explains why garments with similar specifications can perform very differently in use.

MOQ, Lead Time, and Customization in Functional Workwear

MOQ and Functional Consistency

MOQ planning ensures that materials and constructions used for functional garments remain consistent across batches. Below-threshold orders often introduce substitutions that affect performance.

Lead Time and Design Lock

Functional garments require early design lock. Changes to structure or materials after sampling can disrupt the balance between protection, comfort, and durability.

Customization Without Compromising Function

Logos, trims, and reflective layouts must be integrated without blocking ventilation zones or stress points. A functional workwear manufacturer treats customization as part of functional design, not decoration.

Frequently Asked Questions

Is functional workwear always more expensive?

Not necessarily. Well-balanced functional design often reduces replacement frequency and total program cost.

Can one garment serve multiple functional scenarios?

Sometimes, but over-generalization usually compromises performance in at least one condition.

What should buyers confirm before bulk production?

Material behavior, structural layout, grading accuracy, and customization impact should all be validated during sampling.

Closing Perspective

Working with a functional workwear manufacturer is about ensuring that performance claims translate into daily reliability. When materials, structure, and manufacturing processes are aligned around real usage conditions, functional workwear delivers measurable value rather than theoretical features.

AOKENEW develops functional workwear across woven garments, jackets, vests, and reflective apparel by focusing on scenario-driven design and disciplined manufacturing control.

An overview of our manufacturing capabilities and product categories is available on our homepage: https://www.aokenew.com.

If you have related requirements or questions—such as defining functional priorities for specific job roles, balancing comfort with protection, or planning functional garments at scale—our team can provide practical input based on real manufacturing experience.

You are welcome to reach out directly through our Contact Us page: https://www.aokenew.com/contact-us.