Jinhua Aoke New Materials Co., Ltd.

A Brand Manufacturer Since 2010

We have worked with more than 300 domestic and foreign customers, 60% of which are local Top3 customers, and more than 98% of them keep 100% return cooperation rate. Our company is ranking top 5 in the domestic reflective clothing industry.

Certified Excellence

Product Certifications

EN ISO 20471, ANSI, AS/NZS

OEKO-TEX 100, EN 1149

EN 11612, EN 14116

UL, NFPA 2112

Factory Certifications

OEKO-TEX 100

GRS (Global Recycled Standard)

ISO 14001

Quality Control

ISO 9001

BSCI

Strict Quality Control

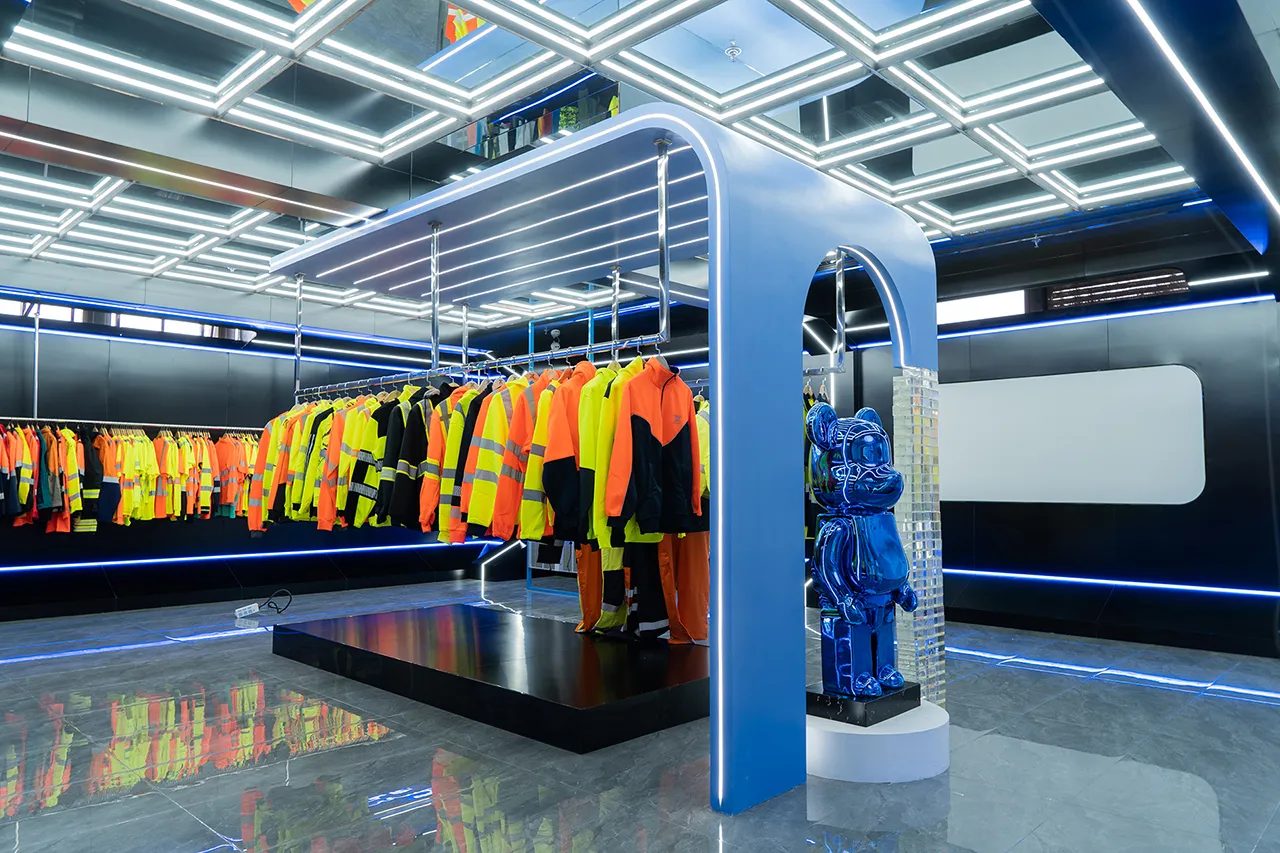

Our Headquarters

The company headquarters office and main warehouse are located in Jinhua, China, responsible for all management and sales work. The main warehouse is responsible for all material testing and shipping.

Technical Innovation

At present, the two technical sample rooms of Aoke are specially designed for personality customized services for customers. Each year, no less than 10 new styles in the market are recommended and are recognized by 70% of the final consumers.

Why Choose Us

Proven Industry Leadership

Since 2010, we've partnered with 300+ domestic and foreign customers, with 60% being local Top 3 companies. Our 98% customer retention rate and top 5 ranking in China's reflective clothing industry speaks to our excellence.

Comprehensive Certifications

Our products meet international standards including EN ISO20471, ANSI, AS/NZS, OEKO-TEX100, EN1149, EN11612, EN14116, UL, NFPA2112. Factory certifications include OEKO-TEX100, GRS, ISO 14001, ISO 9001, and BSCI.

Flexible Production Capacity

Three strategically located factories serve different needs: Jinhua (50K/month) for customization, Chongqing (200K/month) for reflective clothing, and Myanmar (1.5M/month) with 1000 workers for large-scale production.

Innovation & Customization

Our two technical sample rooms specialize in personalized customized services. We launch 10+ new styles annually with 70% consumer recognition rate, ensuring cutting-edge designs that meet market demands.

Rigorous Quality Control

We exceed industry standards with comprehensive testing from raw materials to finished products. Our in-house testing equipment matches professional testing companies, ensuring every garment protects your safety.

Advanced Manufacturing

Our Myanmar facility features 20 sewing lines, 70% template automation, 3 automatic cutting lines, and over 265 flat sewing machines. Young workforce (average age 23) with Chinese management ensures quality and efficiency.

Three Production Facilities

For Better Service, We Have Three Production Capacity Factories with Different Functions

Jinhua Factory

• Monthly: 50,000 pieces

• 50 stitching workers

• Suitable for small orders

• High customization requirements

Chongqing Factory

• Monthly: 200,000 pieces

• 200 stitching workers

• All kinds of reflective clothing

• Medium scale production

Myanmar Factory

• Monthly: 1.5 million pieces

• 1,000 stitching workers

• 20 sewing lines total

• 70% template machines

• Average age: 23 years old

Myanmar Factory Specifications

Equipment & Machinery

- • 265 flat sewing machines

- • 108 double stitching machines

- • Overlock & seam seal machines

- • Knotting & studs machines

- • 3 automatic cutting lines

- • 2 manual cutting lines for custom orders

Warehouse & Management

- • Separated accessory warehouse

- • Finished goods warehouse

- • All management team from China

- • Young workforce (avg. 23 years)

- • Suitable for knitted and woven clothing

Protecting Your Safety

It is the mission to protect your safety from every Aoke's garment